Get Epdm Roof Inspection in Yelm, WA

EPDM roof inspection services for property owners in Yelm, WA, identify leaks, cracks, and wear, ensuring roof safety and longevity through expert evaluations and repairs by local contractors.

If you own property in Yelm, WA, and have an EPDM roof, scheduling an inspection can be a practical step to ensure your roof remains in good condition. Regular inspections help identify potential issues early, preventing costly repairs and extending the lifespan of your roofing system. Property owners often explore EPDM roof inspections to maintain the integrity of their buildings, especially in areas where weather and environmental factors can impact roofing materials over time. Continuing to read can provide useful insights on how local contractors can assist with these evaluations and support your planning process.

When considering EPDM roof inspection services, it's helpful to compare options available within the Yelm area. Local contractors offer a range of expertise in assessing roof conditions, helping property owners make informed decisions about maintenance or repairs. By exploring different service providers, you can find the right professionals to handle inspections tailored to your specific roof type and property needs. Keep reading to learn more about how local experts can support your property’s roofing health and assist with planning your next project.

- EPDM Roof Inspection - when signs of wear or damage are noticed on an aging rubber roof in neighborhoods around Yelm, WA.

- EPDM Roof Inspection - after severe weather events that may have caused punctures or tears in a flat rubber roofing system.

- EPDM Roof Inspection - as part of routine maintenance for commercial or residential properties with EPDM roofing in nearby communities.

- EPDM Roof Inspection - prior to installing a new coating or repair to ensure the roof’s integrity and identify potential issues.

- EPDM Roof Inspection - when preparing a property for sale or insurance assessment to verify the condition of the rubber roofing system.

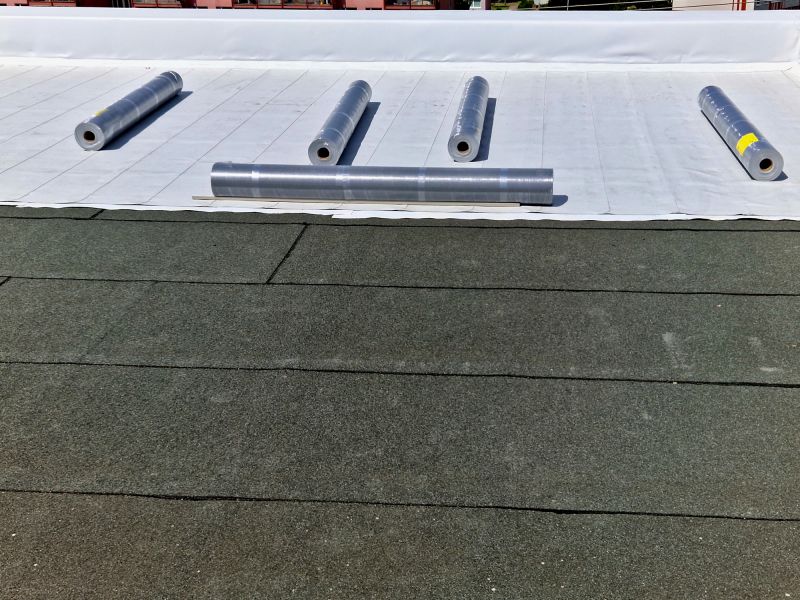

EPDM roof inspection services involve a thorough assessment of rubber roofing systems to identify potential issues before they develop into costly repairs. These inspections typically include a detailed visual examination of the entire roof surface, checking for signs of damage, wear, or deterioration. Service providers may also evaluate the condition of seams, flashings, and edges to ensure everything remains properly sealed. Regular inspections can help homeowners catch early warning signs of problems such as cracks, punctures, or pooling water, allowing for timely maintenance that can extend the life of the roof.

One of the primary benefits of EPDM roof inspections is identifying problems that can lead to leaks or structural damage if left unaddressed. Common issues include cracks in the membrane caused by weather exposure, shrinking or blistering of the rubber, and compromised seams that may allow water infiltration. Inspections can also reveal areas where debris or standing water has accumulated, which can accelerate deterioration. Addressing these problems early can prevent more extensive damage, reduce repair costs, and maintain the integrity of the roofing system over time.

EPDM roof inspection services are often sought for commercial properties, industrial buildings, and residential homes with rubber roofing systems. These roofs are popular for their durability and weather resistance, but they still require regular check-ups to ensure optimal performance. Properties in regions with significant weather fluctuations, such as Yelm, WA, may particularly benefit from routine inspections to withstand the changing seasons. Whether for a flat roof on a business or a residential garage, these services help property owners maintain a secure and watertight roof.

Homeowners and property managers should consider EPDM roof inspections when they notice signs of aging, such as surface cracking, loose seams, or water stains inside the building. Inspections are also recommended after severe weather events, like storms or heavy snowfall, which can cause damage or stress to the roofing material. By partnering with experienced service providers, property owners can ensure their roofs remain in good condition, preventing small issues from escalating into major repairs. Regular inspections provide peace of mind and help preserve the value and safety of the property.

The overview below groups typical Epdm Roof Inspection projects into broad ranges so you can see how smaller, mid-sized, and larger jobs often compare in Yelm, WA.

In many markets, a large share of routine jobs stays in the lower and middle ranges, while only a smaller percentage of projects moves into the highest bands when the work is more complex or site conditions are harder than average.

Smaller Repairs - For routine EPDM roof inspections and minor repairs, local contractors typically charge between $250 and $600. Many small jobs fall within this range, especially for straightforward issues like minor leaks or membrane patches.

Moderate Maintenance - More comprehensive inspections or repairs, such as sealant replacements or addressing multiple damaged areas, usually cost between $600 and $1,200. These projects are common for mid-sized roofs or slightly more complex issues.

Full Roof Inspection - A detailed EPDM roof assessment, including thorough diagnostics and reporting, generally ranges from $1,200 to $2,500. Larger, more detailed inspections are less frequent but necessary for older or larger roofs.

Full Roof Replacement - Complete EPDM roof replacements can cost from $5,000 to $10,000 or more, depending on the size and complexity of the project. Larger, more involved replacements tend to reach the higher end of this range.

Actual totals will depend on details like access to the work area, the scope of the project, and the materials selected, so use these as general starting points rather than exact figures.

Flat Roof Coatings - Local contractors experienced in applying protective coatings on flat roofs often utilize similar inspection techniques and surface preparation skills as those used for EPDM roof assessments.

Commercial Roofing Repairs - Professionals handling repairs on commercial roofing systems frequently perform inspections to identify issues, requiring similar tools and planning as EPDM roof evaluations.

Roof Leak Detection - Service providers specializing in locating and diagnosing leaks use similar inspection methods and equipment as those involved in EPDM roof assessments.

Membrane Roof Installation - Contractors installing membrane roofing systems often conduct thorough inspections to ensure proper adhesion and performance, paralleling EPDM roof inspection processes.

Roof Maintenance Services - Local pros offering routine roof maintenance perform inspections to assess condition and identify potential problems, similar to EPDM roof evaluations.

Waterproofing Projects - Professionals applying waterproofing solutions inspect roofing surfaces to prepare for treatments, sharing planning and assessment skills with EPDM roof inspections.

When comparing service providers for EPDM roof inspection projects, it’s important to consider their experience with similar types of roofs and conditions typical of the Yelm, WA area. Homeowners should look for local contractors who have a track record of inspecting and working on EPDM roofs, as familiarity with the specific material and regional weather patterns can impact the quality and accuracy of the inspection. Asking for details about past projects or seeking references from previous clients can help gauge whether a contractor has the relevant background needed to handle the unique aspects of your roof.

Clear, written expectations are essential when choosing a local contractor for an EPDM roof inspection. Homeowners should request detailed descriptions of what the inspection will include, what issues will be looked for, and how findings will be communicated. Well-defined expectations help prevent misunderstandings and ensure that both parties are aligned on the scope of work. It’s also valuable to verify that the service provider can provide reputable references or reviews from other local clients, which can offer insights into their professionalism, thoroughness, and reliability.

Effective communication plays a key role in the inspection process. Homeowners should seek out local contractors who are approachable and responsive, making it easier to ask questions or clarify concerns throughout the project. Good communication ensures that expectations are understood and that any issues or recommendations are conveyed clearly. Remember, this site introduces homeowners to local options that can handle the work-it's not involved in performing the inspections itself. Choosing a service provider with experience, clear expectations, reputable references, and strong communication can help ensure a smooth and satisfactory EPDM roof inspection experience.

Property owners in Yelm, WA use Epdm Roof Inspection services for practical projects around their homes and businesses. This guide focuses on everyday jobs and straightforward project options.

Property owners in Yelm, WA may seek EPDM roof inspection services when noticing signs of wear or damage on their roofing system. Common situations include leaks after heavy rain, visible cracking or blistering on the rubber membrane, or areas where the roof appears to be pulling away from the edges. Regular inspections can help identify potential issues early, preventing more costly repairs and maintaining the integrity of the roof over time.

Additionally, property owners might look for EPDM roof inspections as part of routine maintenance or before scheduling repairs. Some may want to ensure their roof is in good condition following severe weather events or when preparing for upcoming seasons. Local contractors who specialize in EPDM roofing can provide thorough assessments to help property owners make informed decisions about repairs or replacements.

What is involved in an EPDM roof inspection? An EPDM roof inspection typically includes checking for membrane tears, ponding water, membrane blisters, and overall roof condition to identify potential issues before they worsen.

How often should an EPDM roof be inspected? It is recommended to have an EPDM roof inspected at least once a year or after severe weather events to ensure its integrity and address any damage promptly.

What signs indicate that an EPDM roof needs repairs? Visible signs such as cracks, punctures, pooling water, or membrane lifting can indicate the need for repairs, which local contractors can assess during an inspection.

Can a roof inspection help extend the lifespan of an EPDM roof? Yes, regular inspections can identify minor issues early, allowing for timely maintenance that may help prolong the roof’s service life.

How do local service providers perform EPDM roof inspections? They typically conduct a visual examination, check for damage or deterioration, and may use specialized tools to assess membrane condition and drainage effectiveness.

Identify potential roof issues early - Regular inspections help property owners spot minor problems before they develop into costly repairs.

Plan maintenance or repairs - Inspection reports can guide property owners in scheduling necessary maintenance or fixing leaks promptly.

Assess roof condition after storms - After severe weather, property owners can use inspection services to evaluate roof damage and determine if repairs are needed.

Ensure roof longevity - Periodic inspections can help property owners extend the lifespan of their EPDM roofing by maintaining its integrity over time.

If you are thinking about Epdm Roof Inspection for a property in Yelm, WA, this guide is meant to help you understand the work, the typical project types, and how different options might fit your plans.

When you are ready, you can use the quote form on this page to share a few details about your project. From there, local pros can review the basics and respond with options that match what you have in mind.